표준 제품

우리는 항상 고객에게 고품질의 슬라이더 제품과 솔루션을 제공하는 데 전념해 왔습니다.

이 회사의 제품은 민간 산업뿐만 아니라 항공 우주 및 군사 분야에도 널리 사용되었습니다.

제품 소개

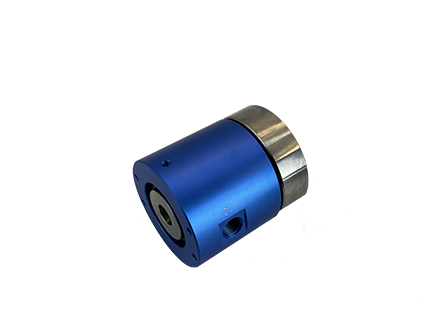

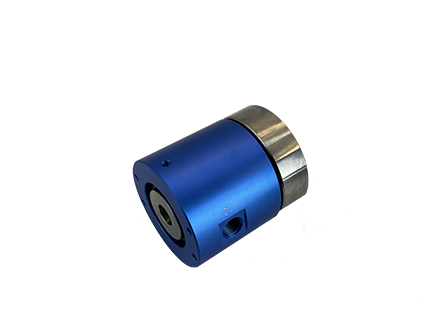

Reehonde의 최신 혁신은 공기압 회전 커넥터다양한 산업용 응용 프로그램의 요구사항을 충족시키도록 설계된 정밀 엔지니어링 솔루션입니다.이 다양한 제품은 공기와 전기 연결을 단일 컴이 단단위에 결합하여 견고한 성능을 유지하면서 원활한 회전을 보장합니다.

The 공기압 회전 커넥터 회전 인터페이스를 통해 유체와 전기 신호를 연속적으로 전송해야 하는 환경에 맞게 설계되었습니다.고품질의 소재와 정밀 제조 기술이 통합된 첨단 설계는 신뢰할 수 있고 효율적인 운영이 필요한 시스템에 이상적입니다.

제품 매개 변수

직장 생활 | 제품 등급 선택 표를 참조하십시오. | 정격 전압 | 0-440VACNDC |

정격 회전 속도 | 제품 등급 선택 표를 참조하십시오. | 절연 저항 | <500mq> |

작동 온도 | -30°C~80°C | 와이어 사양 | AWG17#/AWG22#실버 코팅 테플론 |

작동 습도 | 0~85%RXH | 와이어 길이 | 표준 길이250mm |

연락처 자료 | 제품 등급 선택 표를 참조하십시오. | 절연 강도 | 500VAC@50XHz6S |

케이스 재료 | 알루미늄 합금 | 동적 저항 변경 값 | <0.010<> |

Rotation torque | 0.05N.m+0.02N.m/6Flow passage | Protection level | IP51 |

Product Features

Durable Construction

Shell Material: Constructed from lightweight yet durable 알루미늄 합금, the 공기압 회전 커넥터 offers excellent corrosion resistance and mechanical strength.

Contact Material: 제품 등급 선택 표를 참조하십시오. for specific contact materials tailored to suit your application's needs, ensuring optimal electrical conductivity and wear resistance.

Versatile Performance

Rated Voltage: Supports a wide range of voltages from 0 to 440VAC/DC, making it compatible with various electrical systems.

Rated Speed: 제품 등급 선택 표를 참조하십시오. for speed ratings tailored to your specific requirements, ensuring smooth and reliable operation at high speeds.

Robust Insulation

Insulation Resistance: Less than 500MΩ at 300VDC, ensuring high electrical isolation and safety.

Insulation Strength: 500VAC at 50Hz for 6 seconds, providing additional safety margin against electrical breakdown.

Wide Operating Range

Working Temperature: Rated for temperatures ranging from -30°C to 80°C, allowing for use in a variety of environmental conditions.

Working Humidity: Suitable for operating humidity levels up to 85%RH, ensuring performance in humid environments.

High-Quality Wiring

Wire Specification: AWG17#/AWG22# Silver-coated Teflon wires, offering excellent electrical conductivity and resistance to heat and chemicals.

Wire Length: Standard length of 250mm, customizable to fit your specific application needs.

Smooth Rotation

Rotation Torque: Low torque of 0.05N.m + 0.02N.m/6 rotations, ensuring minimal friction and wear during operation.

Dynamic Resistance Change Value: Less than 0.010, maintaining consistent electrical performance throughout the rotation.

Pneumatic Connectivity

Flow Passage: Designed with multiple flow passages to accommodate pneumatic requirements, ensuring smooth and uninterrupted fluid transfer.

Protection Level

Protection Level: IP51 rated, providing a degree of protection against solid objects and dripping water, ensuring reliability in harsh environments.

Application Areas

The 공기압 회전 커넥터 is versatile and can be utilized in a wide range of industrial applications, including but not limited to:

Automation Systems: Ideal for robotic arms and automated machinery where both electrical signals and pneumatic power need to be transmitted through rotating joints.

CNC Machines: Provides seamless integration for tools and sensors that require continuous electrical and pneumatic connections during machining operations.

Medical Equipment: Suitable for medical robots and patient-handling systems requiring precise and reliable pneumatic and electrical connections.

Aerospace and Defense: Utilized in gimbal systems, radar antennas, and other rotating components where high reliability and performance are critical.

Packaging Machinery: Ensures smooth operation of conveyors, indexing systems, and other packaging equipment that rely on both electrical and pneumatic control.

Installation Method

Installing the 공기압 회전 커넥터 is a straightforward process that requires attention to detail to ensure optimal performance. Follow these steps for a successful installation:

Preparation:

Ensure all necessary tools and materials are available, including screws, seals, and mounting hardware.

Clean the installation area to remove any dirt, debris, or contaminants that could affect performance.

Mounting:

Position the 공기압 회전 커넥터 on the desired mounting surface, aligning it with the rotating shaft and fluid/electrical connections.

Secure the union using the provided mounting hardware, ensuring it is tightly fastened to prevent leakage or movement during operation.

Wiring:

Connect the electrical wires to the corresponding terminals on the 공기압 회전 커넥터, following the wiring diagram provided.

Use wire connectors or soldering to ensure secure and reliable connections.

Apply heatshrink or electrical tape to protect the connections and prevent short circuits.

Pneumatic Connections:

Attach the pneumatic tubing to the flow passages on the 공기압 회전 커넥터, using appropriate fittings and seals to prevent leaks.

Ensure that all connections are tight and secure, and test the pneumatic system for leaks before operating.

Testing:

Before full-scale operation, perform a functional test to verify that the 공기압 회전 커넥터 is working correctly.

Check for any leaks, electrical shorts, or unusual noise that may indicate a problem.

Adjust and fine-tune as necessary to ensure optimal performance.

FAQ

Q: What is the maximum operating pressure for the 공기압 회전 커넥터?

A: The maximum operating pressure depends on the specific model and configuration of the 공기압 회전 커넥터. Please refer to the product grade selection table or consult our technical support team for detailed information.

Q: Can the 공기압 회전 커넥터 be customized to fit my specific application?

A: Absolutely! At Reehonde, we offer customized solutions to meet the unique needs of our customers. Our team of engineers can work with you to design a 공기압 회전 커넥터 tailored to your specific application requirements.

Q: How do I maintain the 공기압 회전 커넥터 to ensure long-term performance?

A: Regular maintenance is key to ensuring the long-term performance of the 공기압 회전 커넥터. Inspect the unit regularly for signs of wear, corrosion, or damage. Clean and lubricate the rotating components as needed, and replace worn-out parts promptly. Additionally, keep the 공기압 회전 커넥터 protected from extreme temperatures, moisture, and contaminants to extend its lifespan.

Q: Is the 공기압 회전 커넥터 compatible with all types of fluids?

A: The 공기압 회전 커넥터 is designed to be compatible with a wide range of fluids, including air, water, oils, and other non-corrosive liquids. However, it is important to consult the product specifications and material compatibility chart to ensure that the 공기압 회전 커넥터 is suitable for your specific fluid application.

Q: Can I install the 공기압 회전 커넥터 in any orientation?

A: The 공기압 회전 커넥터 can be installed in various orientations, depending on the specific model and application requirements. However, it is important to follow the installation instructions and guidelines provided to ensure proper alignment and function. Contact our technical support team if you have any questions about the appropriate installation orientation for your application.

Q: What is the warranty period for the 공기압 회전 커넥터?

A: Reehonde offers a comprehensive warranty for our 공기압 회전 커넥터, covering defects in materials and workmanship. The specific warranty period depends on the product model and purchase date. Please refer to the warranty statement provided with your product or contact our customer service team for more information.

저작권 © 2026 Dongguan Rui-Hong-De Precision Industry Co., Ltd 모든 권리 보유. Privacy policy | Terms and Conditions