표준 제품

우리는 항상 고객에게 고품질의 슬라이더 제품과 솔루션을 제공하는 데 전념해 왔습니다.

이 회사의 제품은 민간 산업뿐만 아니라 항공 우주 및 군사 분야에도 널리 사용되었습니다.

제품 개요

Reehonde 사용자 정의 회전 슬리프 링 회전 응용 프로그램에서 신뢰할 수 있고 지속적인 전기 및 신호 전송을 제공하도록 설계되었습니다.설계 및 맞춤형 솔루션의 높은 유연성으로, 우리의 슬리프 링 자동화 시스템, 로봇 및 회전 기계를 포함한 다양한 산업 및 상업용 응용 프로그램에 이상적입니다.극단적인 조건을 견극하기 위해 만들어진 이러한 슬리프 링 특별한 성능, 내구성 및 장기 신뢰성을 제공합니다.

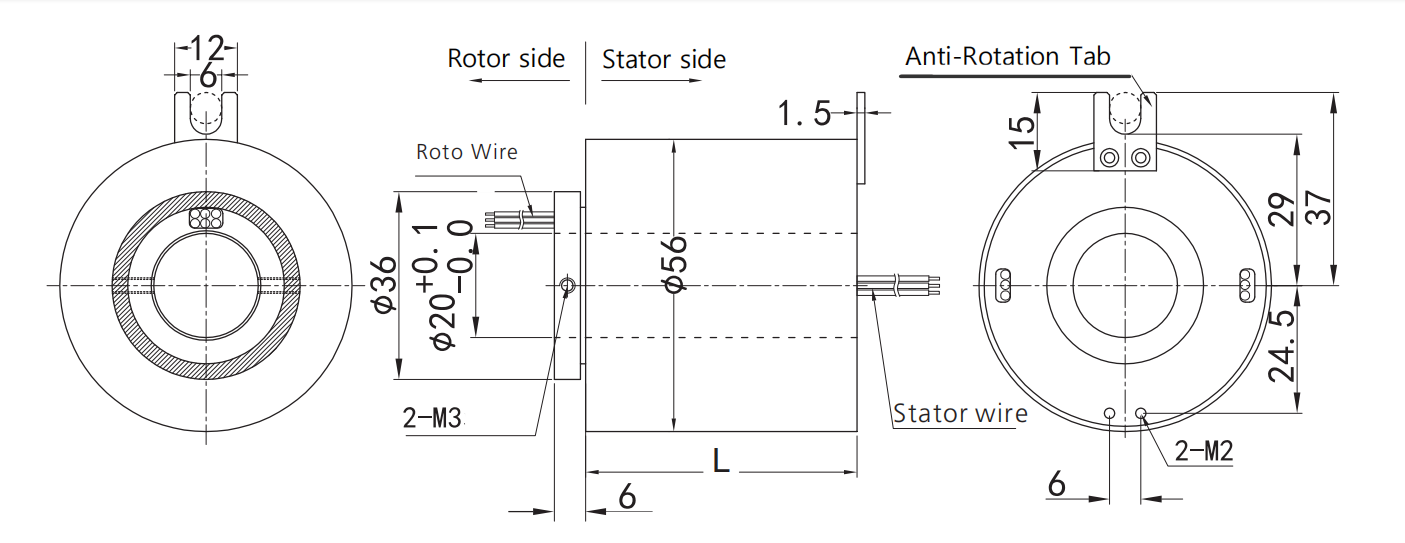

제품 매개변수

직장 생활 | 제품 등급 선택 표를 참조하십시오. | 전력 | 신호 | |

정격 속도 | 제품 등급 선택 표를 참조하십시오. | 정격 전압 | 0 ~ 240VAC / DC | 0 ~ 240VAC / DC |

작동 온도 | -30 ~ C-80 "C | 절연 저항 | > 500MQ/500VDC | > 500MQ/500VDC |

작동 온도 | 0~85%RXH | 철사 명세 | AWG26# 실버 도금 테플론 | AWG26# 실버 도금 테플론 |

연락처 자료 | 제품 등급 선택 표를 참조하십시오. | 와이어 길이 | 표준 길이 300mm (요청에 따라 조절 가능) | |

케이스 재료 | 알루미늄 합금 | 절연 강도 | ||

회전 토크 | 0.05N.m+0.02N.m/6 도로 | 동적 저항 변화값 | <0.01ω<> | |

Protection level | IP51 | |||

Product Benefits

Durability: Designed for high-performance applications, our 슬리프 링 boast an exceptional lifespan, ensuring uninterrupted service over the years, with a lifespan of up to 2,000,000 rotations.

Customization: Whether you require specific signal or power configurations, or unique wire lengths, we offer customized solutions to meet your exact needs.

High-Quality Materials: Featuring high-grade silver-plated Teflon wires and durable aluminum alloy housing, our 슬리프 링 deliver superior electrical conductivity and mechanical strength.

Reliable and Stable: Our 슬리프 링 are built for high stability with minimal signal degradation, ensuring continuous, stable data transfer even in the most challenging environments.

Low Torque & Loss: With ultra-low torque and minimal electrical loss, our 슬리프 링 are highly efficient and contribute to smoother operation with reduced energy waste.

Precious Metal Cluster Brush Multi-Point Contact: The use of precious metal cluster brushes ensures extremely low friction, enhancing long-term performance and reducing wear.

Low Dynamic Resistance: Our 슬리프 링 maintain low dynamic resistance variations, offering smooth and efficient operation with minimal performance fluctuations.

Flexible Performance: Our 슬리프 링 operate in extreme environments, handling temperatures from -30°C to +80°C, and can withstand up to 500VAC insulation strength.

Company Strength

Reehonde is a leader in the development and production of high-precision rotary 슬리프 링. With years of experience in custom solutions, we are committed to delivering top-tier quality products tailored to meet the specific requirements of our clients. Our expert team and cutting-edge manufacturing facilities ensure every slip ring is crafted to perfection, providing the best possible performance and durability for your applications. We are proud to serve industries ranging from automation to defense, offering highly reliable products that stand up to the most demanding environments.

Installation Instructions

Pre-Installation Check:

Ensure the power is off and the system is not under load.

Inspect the slip ring for damage or defects before installation.

Mounting:

The slip ring should be mounted securely to the rotating component. Ensure it is positioned correctly to allow free rotation without interference.

Use appropriate mounting hardware (provided separately if needed).

Wiring Connections:

Connect the wires to the designated terminals as per the electrical design.

Ensure each connection is secure and insulated, preventing any short circuits.

Adjust the wire length to meet the installation needs, and ensure they are routed without undue tension.

Test Run:

Once installed, perform a test run to ensure the slip ring operates correctly, with no abnormal resistance or overheating.

Check that signals are transmitted without distortion and there are no signs of electrical failure.

Maintenance:

Regularly inspect the slip ring for any wear or damage.

Clean the slip ring and its contacts to maintain proper operation, especially in environments with dust or contaminants.

Usage Precautions

Temperature Range:

Ensure the operating temperature is within the specified range (-30°C to +80°C). Operating outside this range could cause premature wear or failure.

Overload Protection:

Do not exceed the rated voltage or current as specified. Overloading may lead to overheating or damage to the internal components.

Environmental Protection:

While the slip ring is rated for protection against dust and moisture (IP51), avoid exposing it to excessive moisture or chemicals that may cause corrosion or degradation.

Avoid Mechanical Stress:

The slip ring must be installed in a way that minimizes mechanical stress or twisting during operation. Excessive mechanical force may lead to failure.

Electrical Safety:

Proper insulation and grounding should be maintained during installation to ensure safety and prevent electrical shock.

Ensure no exposed wires or terminals during operation to reduce the risk of short circuits.

Reehonde’s custom rotary 슬리프 링 provide reliable, high-quality performance for demanding applications. With our tailored solutions, superior materials, and comprehensive support, we ensure that each product meets your specific needs. Whether in industrial automation, robotics, or any other rotating system, our 슬리프 링 are built to deliver exceptional value and performance for years to come.

저작권 © 2026 Dongguan Rui-Hong-De Precision Industry Co., Ltd 모든 권리 보유. Privacy policy | Terms and Conditions